The Microlance played a vital part in the laying of basecourse materials for a 90-kilometre stretch of sealed, high-standard road in Western Australia.

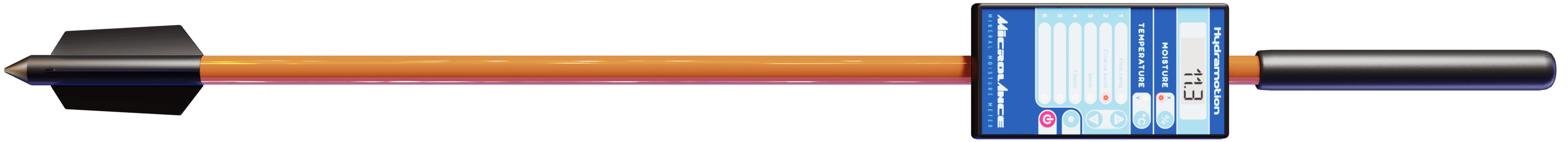

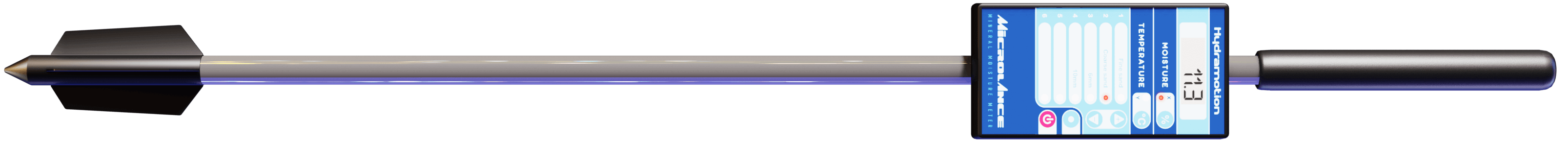

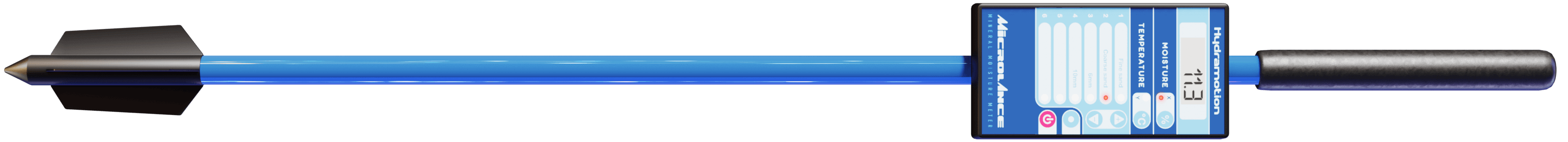

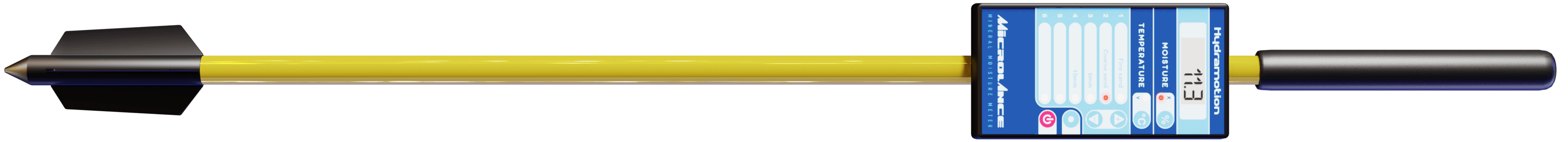

The Microlance played a vital part in the laying of basecourse materials for a 90-kilometre stretch of sealed, high-standard road in Western Australia, linking the mining town of Karratha to the heart of the Millstream Chichester National Park. The Microlance was used to measure the moisture content of materials in the field, avoiding the need for time-consuming laboratory work.

The supply of base course materials presented a significant challenge for the project. Lateritic gravel had to be brought in from an area about 20 kilometres south of the project (outside the National Park), crushed rock had to be bought from a Karratha quarry and a crusher established at the Karratha end. The Microlance greatly sped up the checking of moisture levels in all these materials.

Team Leader Geoff Cocks said that as far as he knew it was the first time the technology has been used in road construction in Western Australia.

“It’s a big plus, because the moisture level has to be correct to ensure the efficient compaction of the road base, “Geoff commented. “Our on-site laboratory would normally take 24 hours to turn around the samples, but this device allows us to do that on the run so we can adjust the water being added by our stabilising machine and get on with the job.”